ProDiscovery in Action

Manufacturing

Leading Ship Manufacturer Raises the Anchor on Productivity with ProDiscovery

↑20%

enhancement of process management efficiency

↑ 1%

increase in productivity

Why ProDiscovery for Manufacturing?

Manufacturers leverage ProDiscovery for the following purposes:

- Leverage underutilized manufacturing data in ERP and MES systems to perform effective data analysis.

- Compare established plans to actual performance to identify areas for improvement and facilitate production management.

- Analyze status of manufacturing equipment and facilities to predict failures and malfunctions.

Discovering hidden patterns in production lines

This study delves into uncovering concealed patterns within production lines through a multifaceted approach. It involves conducting specialized pattern analyses for individual products traversing the manufacturing journey. By scrutinizing process characteristics and quantifying metrics like event counts and timeframes for each case, insights are gleaned.

The investigation comprises three key components;

- process model analysis: employs algorithms to distill event sequences between tasks from transaction records

- performance analysis, encompassing visualizations depicting work-related performance metrics, departmental frequencies, execution and waiting times, supplemented by 2-Dimensional and event sequence analyses, matching rates, and comparative assessments through diverse diagrams

- social network analysis: not only deciphering work flow patterns but also spotlighting operator involvement, inter-departmental and equipment-related flows, ultimately categorizing them within a social network paradigm.

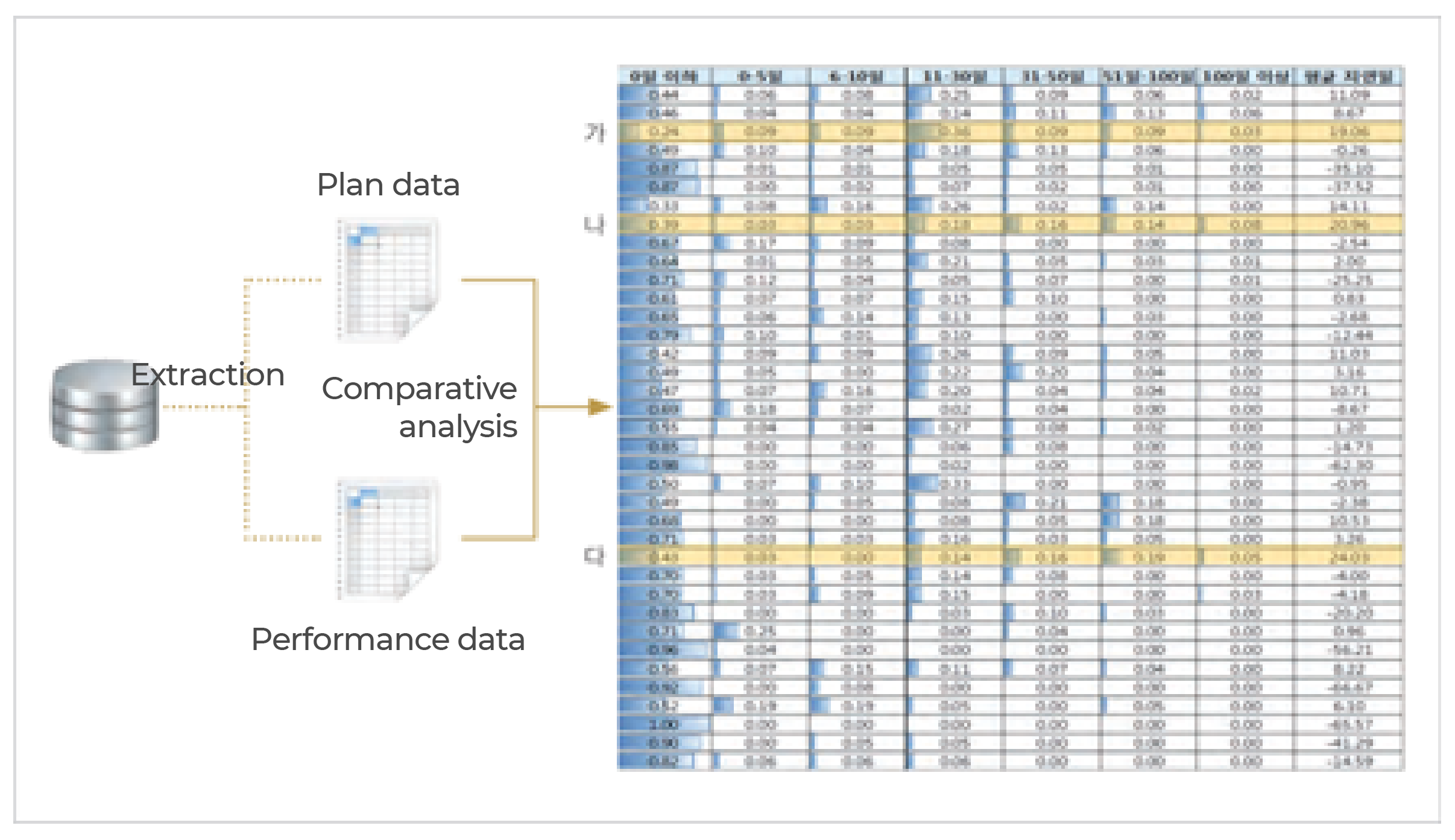

Measuring expected vs. actual performance by locating bottlenecks and re-works

- Identification of process model of plan and actual performance

- Execution of comparative analysis by item (case/department/process)

- Discovery of re-work processes that were not included in the original plan.

[Figure] Comparison of plan and performance process model

Identifying critical factors contributing to process delays to accelerate production

Comparison of delay parameter by item (case/department/process) through comparative analysis of plan and performance

[Figure] Analysis of process delay

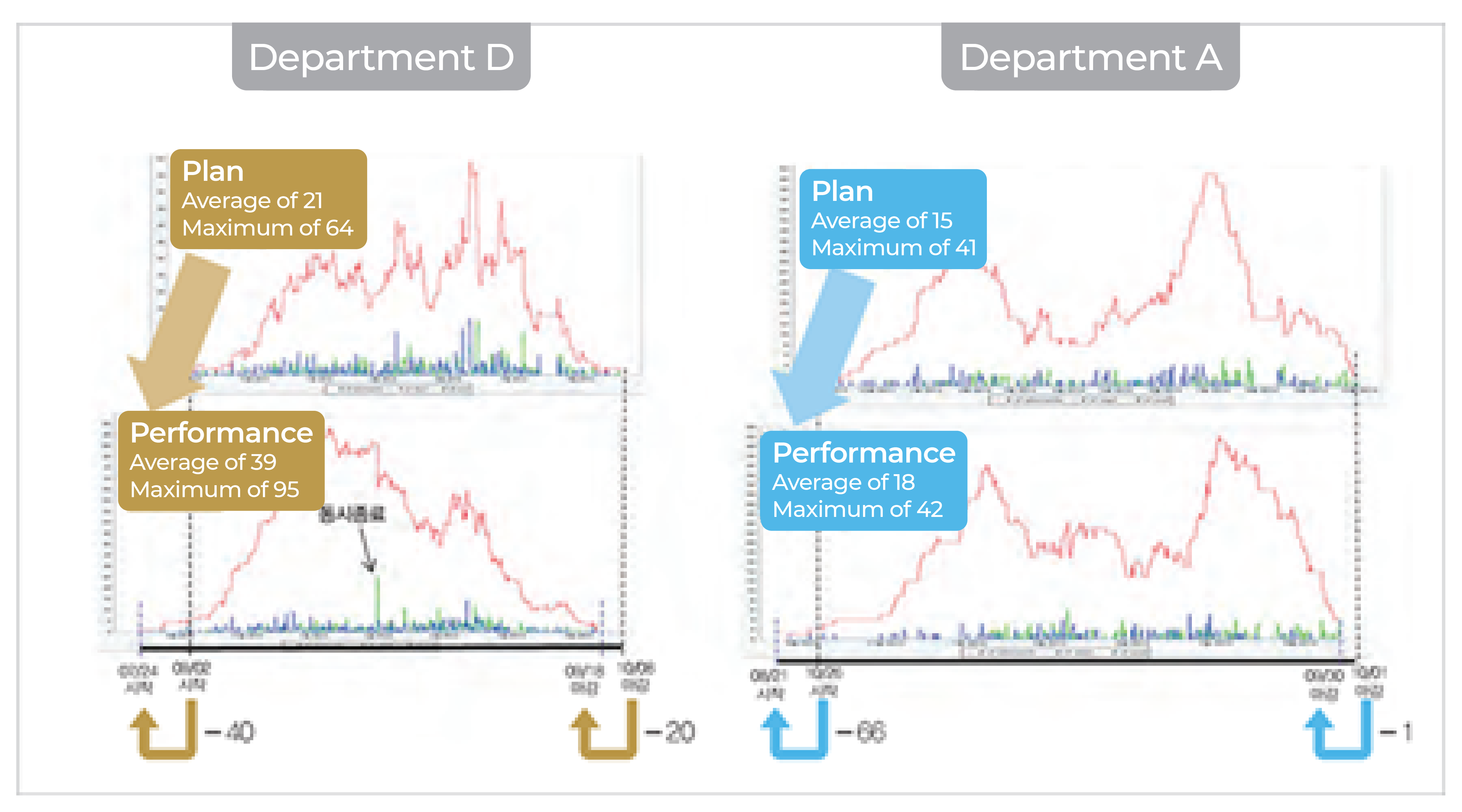

Comparing production load by departments to uncover best practices

- Prediction of process load by department through comparative analysis of plan and performance data

- Identification of department handling quantity that has increased by approximately two folds compared to plan

Load Comparison by Department

Harnessing process- driven insights for optimal production

Advancement of production efficiency was achieved by predicting manufacturing processes through analysis of process and schedule data.

Key achievements:

Key achievements:

- 1% enhancement of productivity through reduced process analysis time

- 20% enhancement of process management work efficiency

- Reduction of process delays and production manhours.

Boost your bottom line with ProDiscovery – where production meets precision.

Have an inquiry?

Get in touch with us.